Cantilever Type Pinch Roll Assembly (Without electrical)

750000 INR/Number

Product Details:

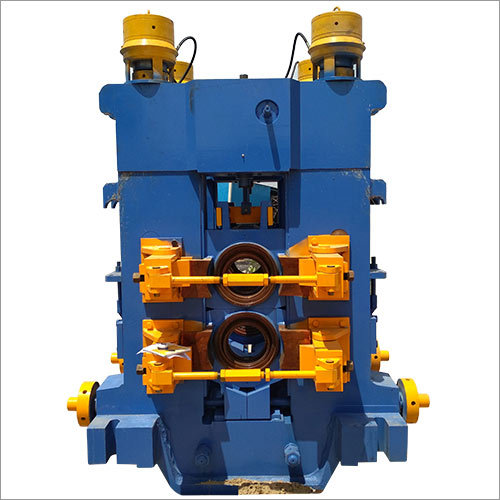

- Type Cantilever Type Pinch Roll Assembly (Without Electrical)

- Material Alloy Steel / Cast Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Voltage 220 Volt (v)

- Weight Approx. 1200 kg (varies by configuration) Kilograms (kg)

- Click to view more

X

Cantilever Type Pinch Roll Assembly (Without electrical) Price And Quantity

- 750000 INR/Number

- 1 Number

- Steel plants, Rolling mills, Strip processing lines

- Heat treated steel

- 250 mm - 350 mm (customizable)

- 300 mm - 600 mm

- Precision Machined

- Manual/Automatic greasing provision

- Ambient to 350°C

- Low, with replaceable wear parts

- Double acting spring loaded

- Side/End supported Cantilever structure

Cantilever Type Pinch Roll Assembly (Without electrical) Product Specifications

- Semi-Automatic

- Approx. 1200 kg (varies by configuration) Kilograms (kg)

- Cantilever Type Pinch Roll Assembly (Without Electrical)

- No

- Alloy Steel / Cast Steel

- 220 Volt (v)

- Steel plants, Rolling mills, Strip processing lines

- Heat treated steel

- 250 mm - 350 mm (customizable)

- 300 mm - 600 mm

- Precision Machined

- Manual/Automatic greasing provision

- Ambient to 350°C

- Low, with replaceable wear parts

- Double acting spring loaded

- Side/End supported Cantilever structure

Cantilever Type Pinch Roll Assembly (Without electrical) Trade Information

- 10 Number Per Week

- 10 Days

- Australia, Central America, South America, Western Europe, Middle East, Eastern Europe, Asia, North America, Africa

- All India

Product Description

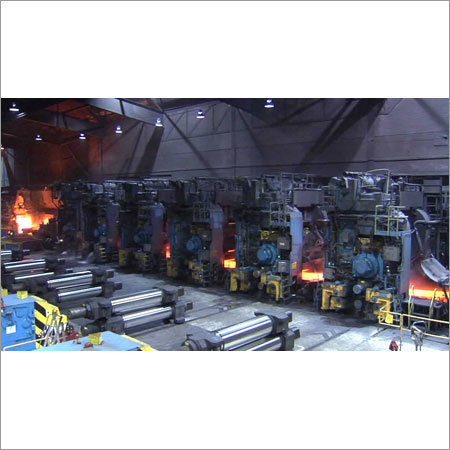

The application of Cantilever Type Pinch Roll Assembly can be noticed in roll mills. This precisely designed machine is capable of resisting bonding between two metals having different attributes. The housing part of its pinch roll is dully welded. The spindle of this machine is used for modifying parameters of pinch rolls. The gear box of this machine consists of forged steel made helical gears and necessary parts. Its high strength mild steel made plate type base is extremely durable. The spherical roller bearing and steel chocks ensure its smooth operation. We are a prominent supplier and manufacturer of excellent quality Cantilever Type Pinch Roll Assembly.

Engineered for Extreme Industrial Demands

Our Cantilever Type Pinch Roll Assembly is meticulously crafted to perform reliably under intense industrial workflows. Suitable for diverse applications, including steel plants and rolling mills, it is built from high-grade alloy or cast steel to withstand challenging operating conditions. The precision-machined finish and spring-loaded mechanism maintain efficient, consistent strip processing even at elevated temperatures, ensuring durability and consistent output.

User-Friendly Maintenance and Flexible Operation

This assembly has been engineered for low maintenance, featuring replaceable wear parts to minimize downtime. Maintenance tasks are simplified with manual or automatic greasing provision, allowing for swift lubrication as needed. Its mechanical control system ensures dependable manual or semi-automatic operation without the reliance on computerized components, catering to a wide variety of process setups.

FAQs of Cantilever Type Pinch Roll Assembly (Without electrical):

Q: How is the cantilever type pinch roll assembly installed in steel plants or rolling mills?

A: The assembly offers versatile mounting, supporting both side and end configurations. This flexibility allows for straightforward integration into various steel plant and rolling mill layouts, ensuring easy adaptation to diverse processing lines.Q: What benefits does this pinch roll assembly provide in strip processing lines?

A: Designed for heavy-duty use, the assembly features a precision-machined finish and heat-treated steel shafts, delivering high durability and low maintenance. It ensures accurate strip guidance and superior pinch performance, optimizing material flow and reducing wear on the system.Q: When should the wear parts be replaced, and is maintenance complicated?

A: Wear parts should be checked and replaced as part of routine maintenance, especially during scheduled shutdowns or when signs of wear are visible. With its modular design and accessible components, replacing wear parts is straightforward, minimizing maintenance time.Q: Where can this assembly operate effectively considering environmental conditions?

A: The pinch roll assembly is built to perform reliably from ambient conditions up to 350C, making it well-suited for hot rolling and strip processing environments frequently encountered in steel manufacturing.Q: What is the process for greasing the assembly, and what options are available?

A: You can lubricate the unit via manual greasing points or opt for an automatic greasing system, depending on operational preference and maintenance protocols. Both methods ensure consistent and adequate lubrication for smooth performance.Q: How does the double-acting spring-loaded pinch mechanism improve usage?

A: This feature enables secure, evenly distributed pressure on the strip with rapid response to process changes, resulting in smooth feeding and reduced risk of material slippage, enhancing operational control during rolling or processing.Q: What makes this assembly an advantageous choice for distributors or exporters in India?

A: The assemblys customizable configuration, robust design, and reliable performance meet the diverse needs of industrial clients. Its adaptability and low-maintenance requirements present a strong value proposition for distributors and exporters serving major steel sector clients.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email