310 MM 2HI Close Type Roller Bearing Stand

Product Details:

- Type 2HI Close Type Roller Bearing Stand

- Material Mild Steel (MS)

- Capacity 310 mm

- Computerized No

- Automatic Grade Semi-Automatic

- Control System Manual

- Power Mechanical Power

- Click to view more

X

310 MM 2HI Close Type Roller Bearing Stand Product Specifications

- No

- Manual

- Mechanical Power

- Approx. 1.8-2.1 Metric Tons

- Semi-Automatic

- Mild Steel (MS)

- 2HI Close Type Roller Bearing Stand

- 310 mm

- Heavy Duty Roller Bearings

- Industrial Blue/Grey Finish

- IS Standard Compliant

- Approx. 1450 mm

- Floor Mounted

- Anti-Rust Coated

- Rolling Mills, Steel Re-Rolling Industries

- 780 mm x 930 mm

- 310 mm

- New

- Up to 350 mm

310 MM 2HI Close Type Roller Bearing Stand Trade Information

- Cash Advance (CA)

- Australia, Central America, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Africa

- All India

Product Description

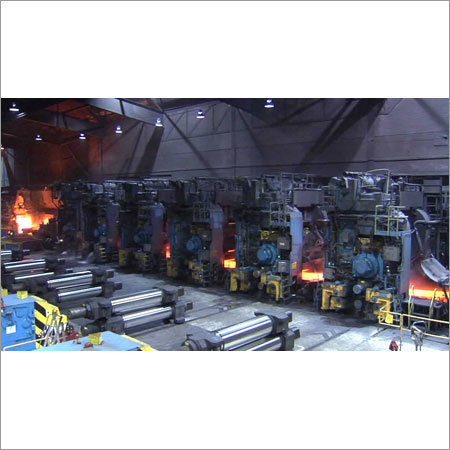

The provided 310 MM 2HI Close Type Roller Bearing Stand has gained popularity in the market for its application specific structure, user friendly operation and long service life. Developed under the close observation of qualified professionals, this roller bearing stand is preferred for its low vibration and noise level, ease of handling, energy efficient functioning and low operation cost. High production rate, precise dimension, competitive price and low repairing charge are undoubtedly some of its main features. We would like to introduce ourselves as a quality conscious supplier and manufacturer of superior grade 310 MM 2HI Close Type Roller Bearing Stand.

Engineered for Rolling Mill Excellence

Specifically designed for demanding rolling mill environments, the 310 MM 2HI Close Type Roller Bearing Stand offers superior durability and stability. Its heavy-duty roller bearings and mild steel construction ensure continuous operation and longevity, enhancing productivity in steel re-rolling industries.

IS Standard Compliance and Anti-Rust Protection

Every stand adheres to strict IS manufacturing standards and features a protective anti-rust coating. This ensures consistent, reliable performance and prolonged lifespan, even under challenging industrial conditions. The stands finish comes in an industrial blue or grey, merging functionality with a professional appearance.

Flexible and Robust Industrial Integration

With its 310 mm width, up to 350 mm roll diameter capacity, and semi-automatic manual operation, the stand seamlessly integrates into existing rolling lines. Its floor-mounted design and mechanical power system contribute to easy installation, high stability, and straightforward maintenance.

FAQs of 310 MM 2HI Close Type Roller Bearing Stand:

Q: How is the 310 MM 2HI Close Type Roller Bearing Stand typically installed?

A: The stand is designed for floor mounting, allowing for easy integration into existing rolling mill setups. Its robust base dimensions and manual control system make installation straightforward with standard mechanical tools.Q: What are the main applications of this roller bearing stand?

A: It is primarily used in rolling mills and steel re-rolling industries, supporting the movement and shaping of metal sheets or bars. Its heavy-duty construction accommodates high-capacity, continuous industrial processes.Q: When should this roller bearing stand be used over other types?

A: Choose this model for projects requiring a 310 mm housing width and support for roll diameters up to 350 mm, particularly where heavy-duty roller bearings and compliance with IS standards are essential for performance and longevity.Q: Where is this stand manufactured and who can supply it?

A: This roller bearing stand is manufactured, supplied, exported, and traded by reputable distributors in India, ensuring quality and adherence to industry benchmarks.Q: What is the benefit of the anti-rust coating and industrial finish?

A: The anti-rust coating offers added protection against corrosion, significantly extending the stands operational life in harsh mill environments. The industrial blue or grey finish provides both aesthetic appeal and practical durability.Q: How does the manual control system operate this stand?

A: The stand uses a manual mechanism in a semi-automatic configuration, allowing technicians to control and adjust operations for precise rolling, without complex computerized systems.Q: What process does this stand support in steel mills?

A: It aids in the rolling process by firmly supporting the rolls, ensuring smooth and consistent shaping or reduction of steel bars and sheets, thus improving overall production quality and throughput.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email