Prestress Type Hydraulic Locking 550 Center 3HI

Product Details:

- Type Prestress Type Hydraulic Locking

- Material Mild Steel

- Capacity 550 mm Center Distance

- Computerized No

- Automatic Grade Automatic

- Control System Hydraulic

- Voltage 220-440 V

- Click to view more

X

Prestress Type Hydraulic Locking 550 Center 3HI Product Specifications

- Prestress Type Hydraulic Locking

- Approx. 11-13 Tons

- No

- 550 mm Center Distance

- Automatic

- 220-440 V

- 7.5 kW

- Mild Steel

- Hydraulic

- 550 mm

- 3HI

- Water Cooled

- Touch Screen Interface

- Hydraulic Prestress Type

- 300 bar

- 2900 x 1800 x 2100 mm

- Steel Rolling Mill, Industrial Manufacturing

- 1250 mm

- 550 mm

- ±0.02 mm

- 1440 rpm

- Overload Protection, Emergency Stop

- Cast Steel Housing

- Anti-corrosive Paint

- 1500 tons

Prestress Type Hydraulic Locking 550 Center 3HI Trade Information

- Cash Advance (CA)

- Central America, South America, Western Europe, Middle East, Africa, Eastern Europe, Asia, North America, Australia

- All India

Product Description

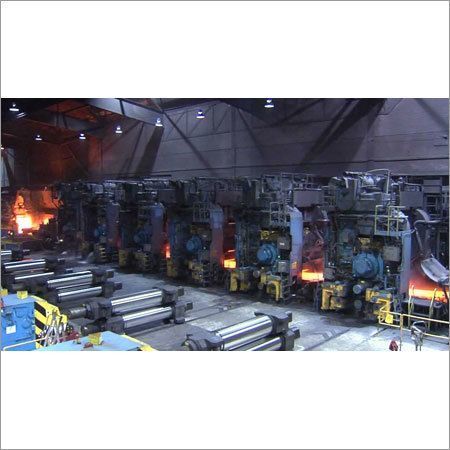

Prestress Type Hydraulic Locking 550 Center 3HI is acknowledged for its high production rate and high efficiency level. This rolling mill equipment has been designed by qualified technocrats as per industry specified standards. User friendly operation and low operation cost are the main reasons behind its increasing demand in the market. Easy to set up, this rolling mill equipment has high structural strength and it can endure high temperature and rust prone environment. Welded structure, long working life, hassle free maintenance technique and energy efficient operation are its unique features. We are a reliable supplier and manufacturer of excellent quality Prestress Type Hydraulic Locking 550 Center 3HI.

Engineered for Industrial Precision

Crafted for demanding industrial and steel rolling applications, this 3HI stand offers precision with a bed length of 1250 mm and a high level of tolerance at 0.02 mm. Its anti-corrosive finish and sturdy cast steel construction extend the lifespan, making it suitable for rigorous operational environments.

Hydraulic Prestress Locking Advantage

The advanced hydraulic prestress locking mechanism ensures stable and secure handling under extreme pressure, reaching up to 300 bar oil pressure and supporting rolling forces as high as 1500 tons. This system maintains precision and reliability, minimizing downtime and maximizing throughput.

Advanced Safety and User Operation

Prioritizing operator safety, the machine integrates overload protection, an emergency stop function, and a user-friendly touch-screen panel. These features facilitate efficient workflow management while protecting both operator and equipment.

FAQs of Prestress Type Hydraulic Locking 550 Center 3HI:

Q: How does the hydraulic prestress locking mechanism operate in this 3HI rolling mill?

A: The hydraulic prestress locking mechanism utilizes high-pressure oil (up to 300 bar) to firmly secure the rolls in place, enhancing stability during rolling. This process minimizes roll displacement and ensures consistent quality, even under heavy rolling forces up to 1500 tons.Q: What benefits does the touch screen operator panel offer?

A: The integrated touch screen interface simplifies machine operation by providing real-time status updates, configuration options, and quick access to safety features. It enhances user control and efficiency, reducing training time and operational errors.Q: Where is this hydraulic locking rolling mill typically used?

A: This machine is primarily employed in steel rolling mills and large-scale industrial manufacturing facilities. Its robust construction and precise tolerance make it suitable for processing various steel products under demanding production conditions.Q: When is it necessary to use the emergency stop and overload protection features?

A: Operators should activate the emergency stop in unexpected or hazardous situations, such as mechanical malfunction or imminent danger. The overload protection automatically engages when rolling forces exceed safe limits, protecting the equipment from potential damage.Q: What is the process for cooling the machine during operation?

A: The rolling stand incorporates a water cooling system, which circulates water through designated channels to dissipate heat generated during intensive rolling. This maintains optimal operational temperatures and safeguards the integrity of internal components.Q: How does the anti-corrosive paint finish benefit the machine?

A: The anti-corrosive paint provides an added protective layer against rust and environmental degradation, particularly in high-moisture or chemically aggressive industrial settings. This prolongs the machines operational lifespan and reduces maintenance frequency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email