Start Stop Flying Shear To Cut 8mm to 20mm

Product Details:

- Type Start Stop Flying Shear

- Material High-Grade Alloy Steel

- Capacity Cuts Bars from 8mm to 20mm Diameter

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Based

- Voltage 220-480 V

- Click to view more

X

Start Stop Flying Shear To Cut 8mm to 20mm Product Specifications

- Approx. 3500 kg

- PLC Based

- High-Grade Alloy Steel

- Cuts Bars from 8mm to 20mm Diameter

- Start Stop Flying Shear

- 220-480 V

- Yes

- Automatic

- 15-25 kW

- Up to 25 m/min

- Servo Motor

- Rust-Proof Coating

- On-site by Manufacturer

- Start-Stop Automated

- 4800mm x 1450mm x 2100mm

- Hardened HSS

- Emergency Stop, Overload Protection

- Automatic Oil Cooling

- Customizable up to 12 meters

- TMT Bars/ Rebars Cutting

Start Stop Flying Shear To Cut 8mm to 20mm Trade Information

- Cash Advance (CA)

- 10 Per Week

- 10 Days

- Western Europe, Central America, Australia, North America, Middle East, Eastern Europe, South America, Asia, Africa

- All India

Product Description

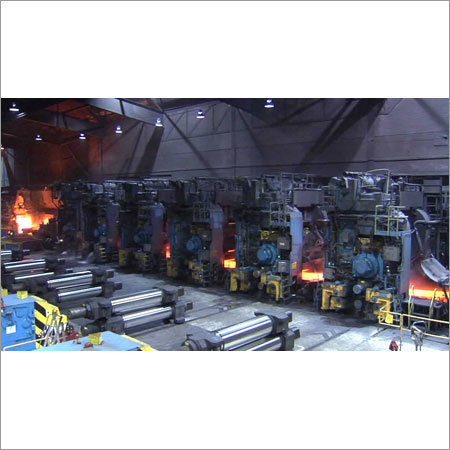

Start Stop Flying Shear To Cut 8mm to 20mm TMT bar is appreciated for its ergonomic structure and uninterrupted operation. The cutting section of this machine moves towards the flow of products either in angular direction or in parallel manner. This machine consists of dual shafts, roller bearing, adjustable arm and blade holders. The entire structure of this machine is welded that denotes its high structural strength. Easy to control, this machine has long working life, precise dimension and all its components are made of superior grade raw materials. We are a prestigious supplier and manufacturer of Start Stop Flying Shear To Cut 8mm to 20mm TMT bar.

Advanced Cutting Performance

Leveraging servo motor technology and hardened HSS blades, this Start Stop Flying Shear delivers fast and precise cuts for TMT bars and rebars. The PLC-based computerized system enables accurate operation and minimal manual intervention, optimizing productivity and reducing downtime in automated manufacturing environments.

Robust Build and Safety Features

Constructed from high-grade alloy steel and finished with a rust-proof coating, this machine is tailored for durability and long-term usage. Automatic oil cooling ensures optimal blade temperature, while emergency stop and overload protection systems support safe operation. The installation process is streamlined by the manufacturer, guaranteeing compliance and efficiency.

FAQs of Start Stop Flying Shear To Cut 8mm to 20mm:

Q: How does the automatic Start Stop Flying Shear enhance cutting accuracy for TMT bars and rebars?

A: It uses a PLC-based control system and a servo motor to automate precise positioning and rapid blade movement, ensuring consistent cuts for diameters ranging from 8mm to 20mm at speeds up to 25 m/min.Q: What is the process for installing this flying shear machine at my facility?

A: Installation is carried out on-site by the manufacturers technical team, who ensure the machine is correctly set up, calibrated, and integrated with your operational requirements.Q: When should the machines automatic oil cooling system be maintained or checked?

A: Routine maintenance checks of the automatic oil cooling system are recommended according to the manufacturers service schedule to guarantee peak performance and blade longevity.Q: Where can I integrate this shear cutter in my production line?

A: The machine is suitable for integration at any stage requiring precise TMT bar or rebar cutting. Its compact design (4800mm x 1450mm x 2100mm) allows flexible placement within diverse industrial layouts.Q: What are the key benefits of using a hardened HSS blade for cutting?

A: Hardened HSS blades offer superior cutting edge retention and wear resistance, enabling faster and smoother cutting of alloy steel bars, which minimizes blade changeover and extended service intervals.Q: How is operator safety ensured during machine operation?

A: Safety is ensured through emergency stop controls, overload protection, and PLC-based automation, reducing manual intervention and the risk of operational hazards.Q: Can the maximum bar length be customized according to different project demands?

A: Yes, the cutting machine allows customization of maximum bar lengths up to 12 meters to accommodate varying project specifications and material requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email